Slump test is the most commonly used method of measuring consistency or workability of fresh concrete which can be employed either in laboratory or at the site of work.

Slump test concrete used as retaining wall.

This test is conducted to establish the consistency of fresh concrete and to find out its flow.

This test plays a vital role in.

It is not a suitable method for very wet or very dry concrete.

A slump test is a method used to determine the consistency of concrete.

The stiffness of the concrete mix should be matched to the requirements for the finished product quality.

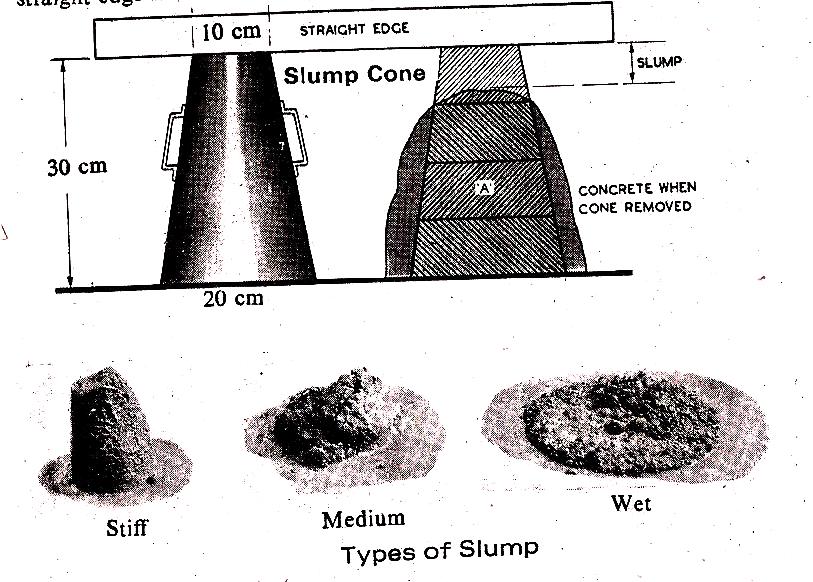

This test also called frustum whose upper diameter is 50 mm and the bottom diameter is 100 mm and the height is 300 mm.

It is also critical in measuring the workability of the concrete and lets you know the composition of the.

Slump is a measurement of concrete s workability or fluidity.

One of the critical tests to analyze the quality of concrete is the concrete slump test.

The concrete slump test is an on the spot test to determine the consistency as well as workability of fresh concrete.

It is performed before casting of concrete into formwork.

Technique used for the concrete slump test.

It is used conveniently as a control test and gives an indication of the uniformity of the concrete from batch to.

The contractor who plans to build the foundation walls for our house makes a practice of using concrete with a slump of 6 1 inch.

I ve argued that this would be too wet but he says that his trade association approves this practice and that stiffer concrete can t be consolidated properly.

Here i shall tell you how to perform a slump test of concrete at site as per 1199 1959.

This test can be used as a control test and gives an indication of the concrete uniformity from batch to batch.

Slump cone with its base plate.

Repeated batches of the same mix brought to the same slump will have the same water content and water cement ratio weights of aggregate cement and admixtures are uniform and aggregate grading is within acceptable limits.

Slump test is done to understand the workability of the concrete brought at site from rmc plant or batching plant at site workability is a term used to determine the ease with which a concrete can be batched transported placed compacted and cas.

Of concrete on the ground.

The slump test is the most simple workability test for concrete involves low cost and provides immediate results.

It s an indirect measurement of concrete.

And more importantly the step by step procedure of slump test followed by the list of cautions during the test and way to measure the workability from the test result.

Concrete slumps have ranged from 4 to 6 in the specification requirements and the last truck is on site with about 12 000 cu.